WORK PRODUCED BY MASON MACHINE & TOOL:

- Short-Run Machined Parts

- Quick Turn-around Jobs

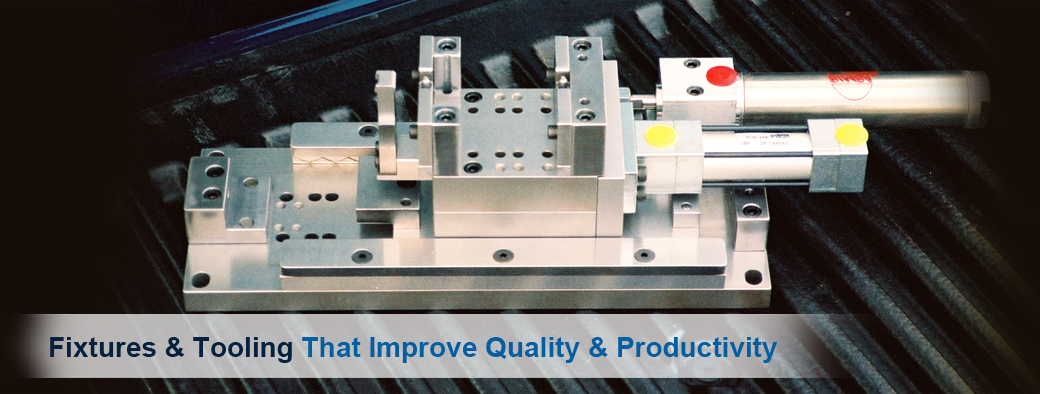

- Assembly Tools (Manual or Automated)

- Inspection/Calibration Fixtures

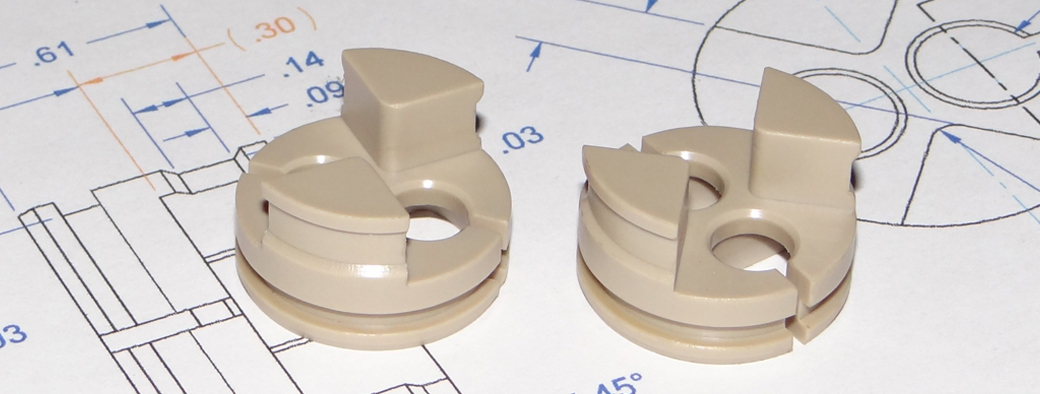

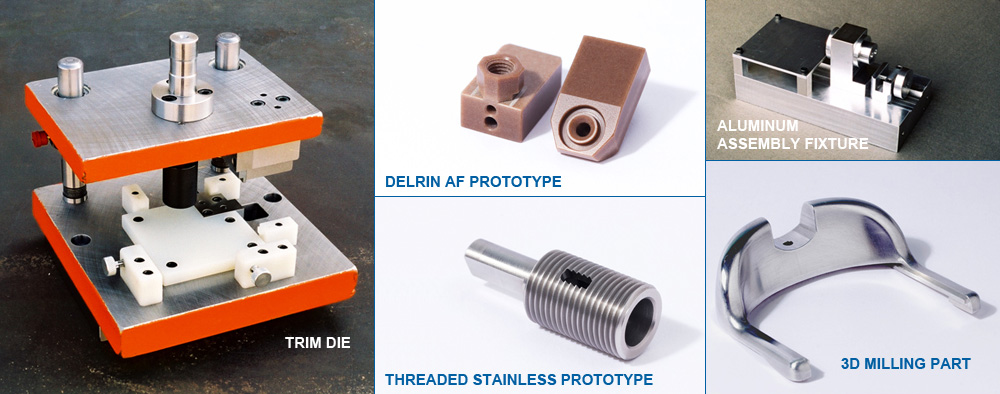

- R&D/Prototype Parts

- Laminating Fixtures

- Specialized Machinery

- Potting Molds

- Hog-out Work

- Workholding Fixtures

- Weldments

- Dies (Blanking, Trimming, etc.)

- Maintenance Machining

- Reverse Engineered Parts

IN-HOUSE MANUFACTURING PROCESSES:

- Milling – Conventional & 3 Axis CNC (Travels: 29″ x 20″ x 19″)

- 4th Axis Milling Using Indexers and Rotary Tables

- Turning – Conventional (1/8″ – 7″ Diameter To 36″ Long)

- Surface Grinding (Area: 6″W x 12″L)

- Sawing

- Deburring

- Computer-Aided-Design (CAD)

- CNC Programming

MATERIALS MACHINED:

- Plastics (ABS, Nylon, Delrin, Ultem, PVC, Acrylic, etc.)

- Copper, Brass and Bronze

- Aluminum Alloys

- Cast Iron

- Carbon Steel

- Alloy Steel

- Stainless Steel

- Tool Steel

SOME OF OUR SATISFIED CUSTOMERS:

- ALCOA

- BABCOCK, INC.

- BECKMAN COULTER

- DOMINO LASERS

- MAGNECOMP CORP

- SAINT-GOBAIN

- SYMBOL TECHNOLOGIES

- THOMAS & BETTS

(714) 879-8260

(714) 879-8260