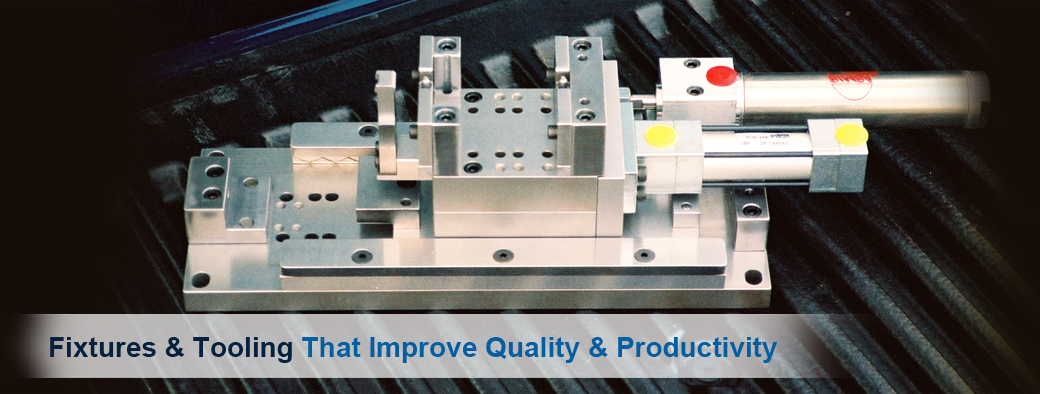

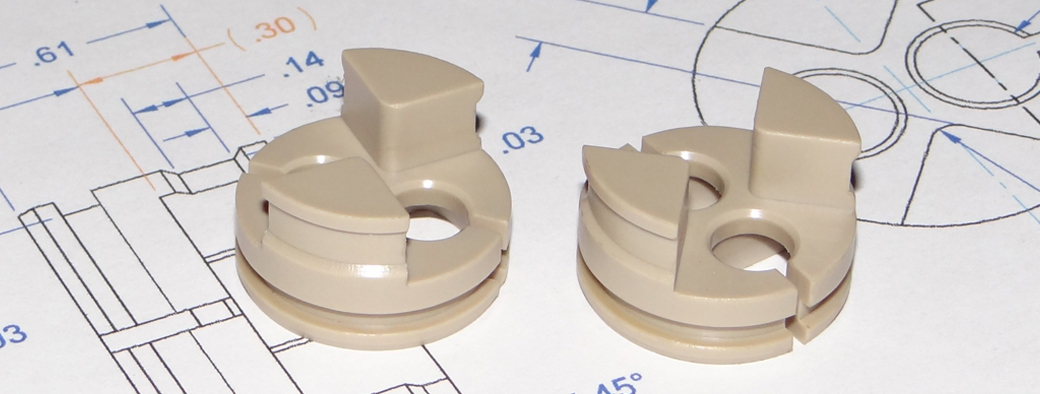

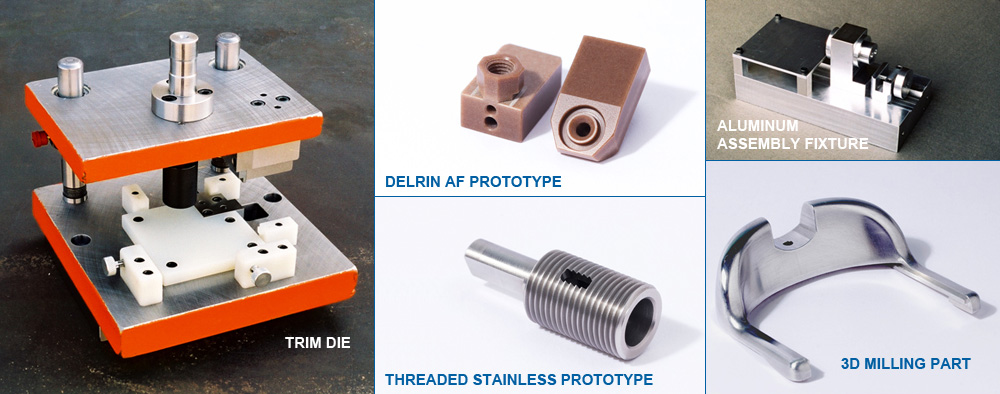

Whether we are making a one-of-a-kind tool, or machining a short run job, attention to detail is paramount. It’s not uncommon for us to catch customer engineering errors before any machining is done, thereby avoiding costly rework and delays.

Whether we are making a one-of-a-kind tool, or machining a short run job, attention to detail is paramount. It’s not uncommon for us to catch customer engineering errors before any machining is done, thereby avoiding costly rework and delays.

Our Quality Policy and Procedure Manual complies with ISO 9001:2015. The measuring instruments that we use are calibrated regularly, and our strict quality control procedures ensure the accuracy and quality of every project. At MASON MACHINE & TOOL, we are constantly striving to achieve zero defect manufacturing. Our attitude is that shipping parts that are “out of print” is simply not an option.

If you need tooling, prototypes or short run machined parts, send us a Request For Quote. Let us demonstrate our work ethic and impress you with our standards of quality.

Inspection Equipment :

- 24” X 36” Granite Surface Plate

- Mitutoyo 24” Dial Height Gage

- Brown & Sharpe Gage Blocks

- Pin Gages

- Bore Gages

- 0” – 6” Outside Micrometers

- Groove and Depth Micrometers

- 0” – 12” Dial Calipers

- Test and Travel Indicators

- Protractors and Sine Bars

(714) 879-8260

(714) 879-8260